BX-6X series specially adapt to MODBUS industrial equipment and systems

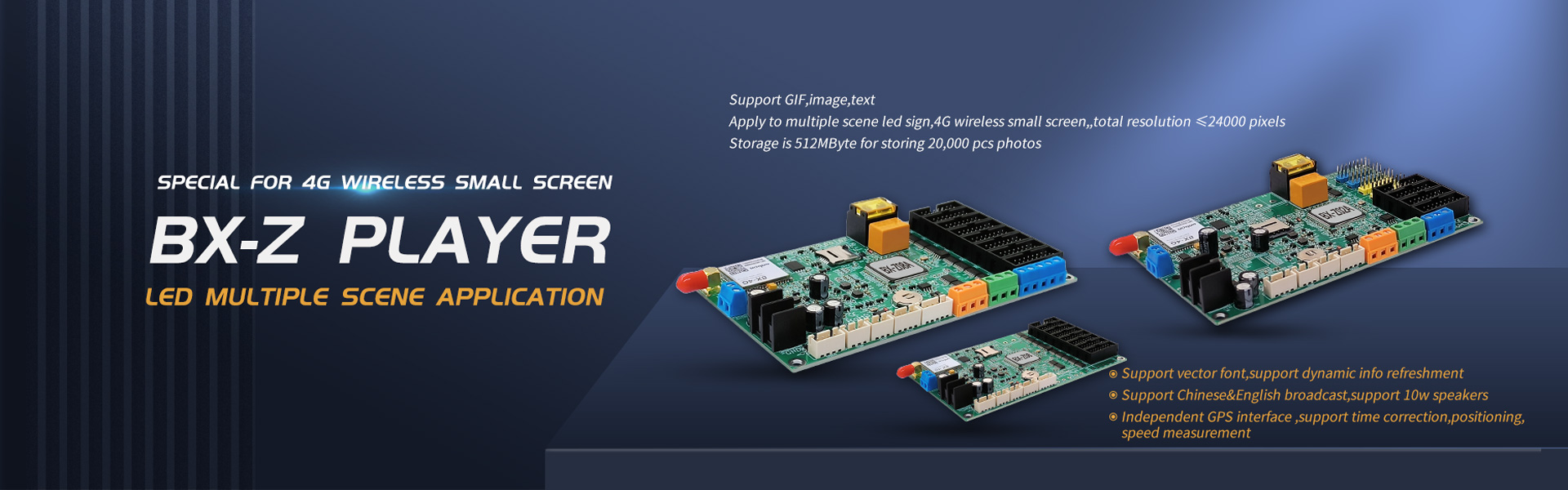

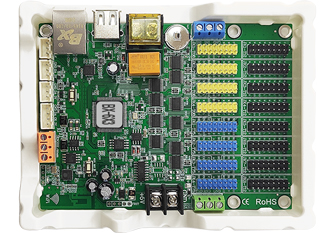

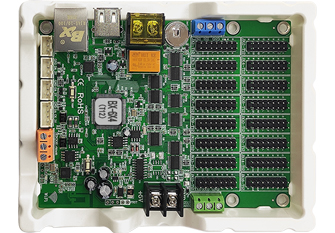

2020 version of BX-6 series controller focus on creating "Multi scene" ▪ "Full function" LED display project controller.

Comply with 《T COEMA 102S-2018 general technical requirements for asynchronous no grayscale LED display controller (card)》

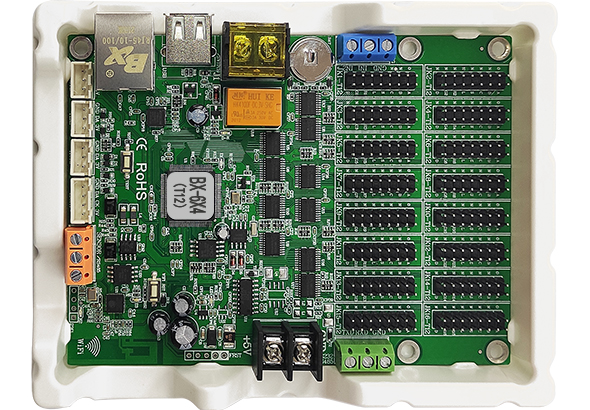

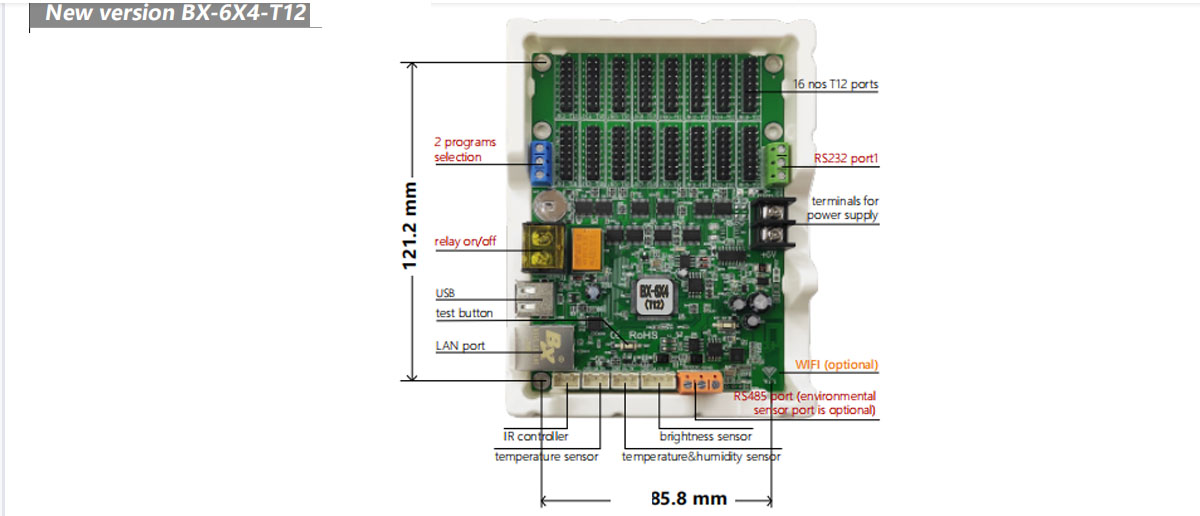

As a small branch of BX product line, MODBUS controller mainly includes 6 models: BX-6X1 / 6X2 / 6X3 / 6X4-T12 / 6X4-T08 / Y1M.

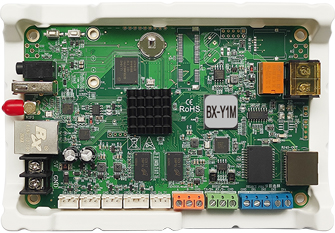

BX-Y1M is mainly used in full-color LED display screen, support bigger controller size and more parameter data.

1.Professional

(1) Support Modbus protocol, and easily adapt to MODBUS industrial equipment / DCS industrial system / environmental data acquisition instrument, etc. Compared with the traditional application system, it saves one industrial PC and avoids complex secondary development;

(2) On-board network port and RS485 serial port ,supports MODBUS protocol. Support each communication port to send data at the same time, which is applicable to various industrial sites;

(3) MODBUS controllerS support two system access modes of master or slave, and supports 0x03, 0x04, 0x06 and 0x10 function codes of Modbus protocol.

Host mode means that the controller is the host and takes the initiative to obtain equipment data;

Slave mode means that the controller is a slave and passively receives the data transmitted by MODBUS equipment;

(4) Parameter data limitation

The RS485 serial port of Modbus controller supports ≤ 20 devices, and the number of devices supported by MODBUS controller network port is unlimited;

BX-6X series products support parameter data ≤ 256, and BX-Y1M supports unlimited parameter data;

(5) Baud rate of serial port

BX-6X series products support serial port baud rates: 9600 and 57600, and BX-Y1M supports more serial port baud rates;

(6) Data type and data operation

The data type supports single precision floating-point type, signed short integer, signed long integer, unsigned short integer and unsigned long integer of ABCD / DCBA / BADC / cdab decoding order.

Data operation supports +, - ×、 ÷,%, 1 / N, A2,, and other common calculation formulas.

(7) Initialization setting

Select Modbus RTU master / slave mode and Modbus TCP master / slave mode as required, and input the corresponding ID, IP, port, function code, register starting address, timeout time, time interval, data type, data high and low order, etc. according to the Modbus device.

(8) Data display style

The type setting design of parameter data display style on LED screen is completed by using Ledshow software. We will develop and improve the humanized design and user operation experience of this section.

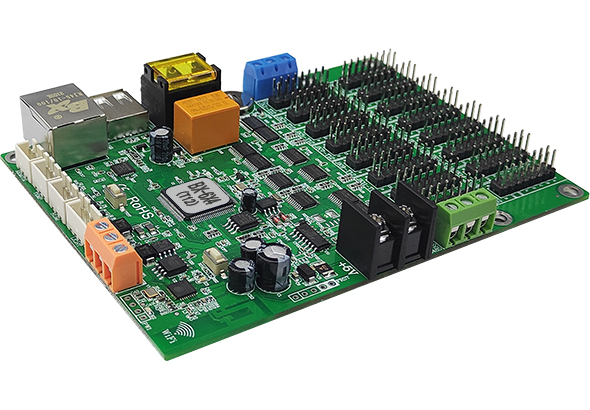

2.More interfaces and excellent technology

(1)Full communication interface on board. Ethernet+RS232/RS485+USB +WIFI(optional ) port

(2)Brightness/temperature/temperature&humidity sensor ,IR controller socket and RS485 environment sensor interface on board.

(3)UV three proofing adhesive, GB double 85 protection grade, dust, moisture, static electricity, salt spray; (new technology fully used since January 2021)

(4) Adopt plastic package. Advantages: fire resistance, environmental protection, anti-static, high temperature resistance;

3.Stability

(1)-Ambient temperature is 40 ℃ ~ 80 ℃;

(2)3.5V-5.5V wide voltage;

(3)7*24 hours continuous power supply, ≤ 0.3% failure rate;

(4)IP group setting, MAC conflict detection;

(5)Coated with UV three proofing glue, GB double 85 protection grade, dustproof, moisture-proof, anti-static, anti salt fog;

(6)Isolate invalid network data, adapt to busy and complex networks, and make communication more stable.